KITZ SCT’s concept of research and development

We are committed to carrying out new technology research surveys throughout our development departments, sales departments and production departments in order to continue to provide highly reliable products that satisfy all of our customers.

Manufacturing meeting customer demands for not only general-products but also special and high value added systems.

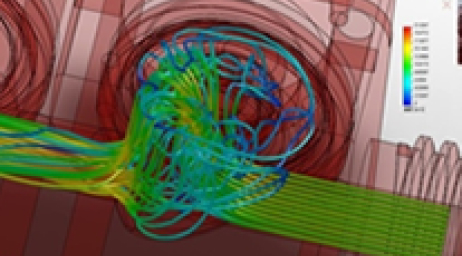

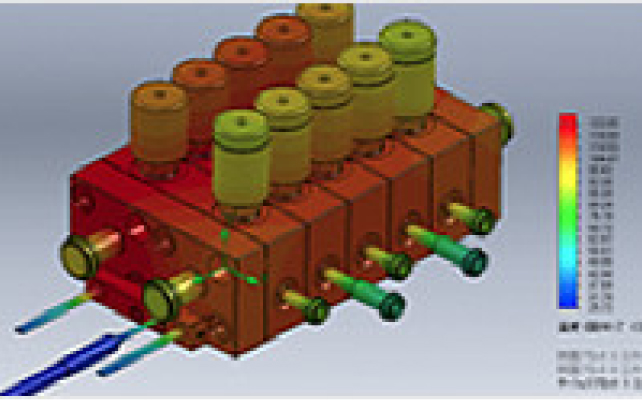

KITZ SCT is creating fluid control devices that offer the highest level of safety, durability and reliability. A unique development and testing system to continue to create high-value added products has been constructed. KITZ SCT promises to continue to provide our customers with products that meet customer demands based on the spirit of challenge as a development-oriented company.

Product development evolving with the world’s leading technological capabilities.

APC Butterfly Valves

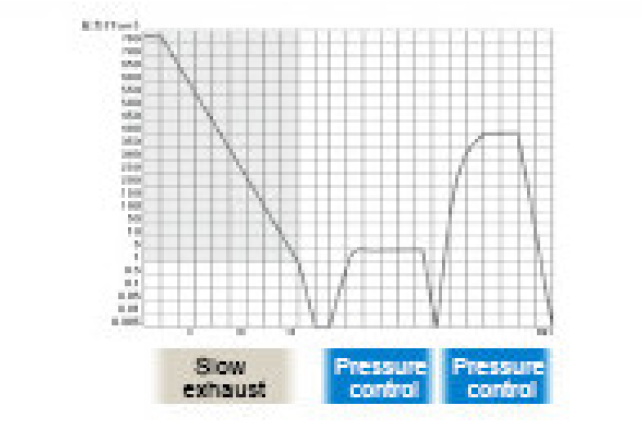

The APC Valve replaces and performs the function of four different valves: Isolation and slow start for bypass line, Isolation and auto pressure control for main line. The optional internal and external heaters maintain fluid temperature with a maximum temperature of 190C.

Read More

IVBH

The IVBH series vacuum valves have built-in spiral heaters that follow the movement of the bellows. The valve's external and the bellows internal heating units take place with the valve in either the open or closed state. These valves eliminate cold spots by heating externally and internally for a more uniform temperature. This feature will reduce byproduct buildup. The internal and external heaters have individual channels and can heat independently to an arbitrary temperatures up to 180C. In addition, a magnetic proximity open/close switch, and thermostat are available as options.

Read More

200C Submersible Valve, Preset Cv, PFA Seat

The KDS series of valves are fully submersible up to 200C and a factory preset Cv for consistent flow over millions of cycles at max temperature. The valve has a fast actuation speed of under 30 milliseconds and available in 1/4 and 1/2 size.

Read More

High-Speed, High-Durability Valves 200C

The TDF series is KITZ SCT's high speed/high durability valve perfect for ALD and similar type processes requiring pulsing. The actuation time of the TDF valve's sealing diaphragm is 5 milliseconds, and full cycle speed is 18 milliseconds. The valve's cycle life rating is 100 million cycles.

Read More

KITZ SCT’s development system

KITZ SCT develops new products with its development & design, quality assurance, production management, manufacturing, and sales departments all in a cooperative effort. By developing new products from various perspectives, we quickly provide products that meet customer needs. We are also committed to developing new products on a day-to-day basis through the adoption of new technologies.

Sales

Development & Design

Manufacturing

Production Management

Quality Assurance