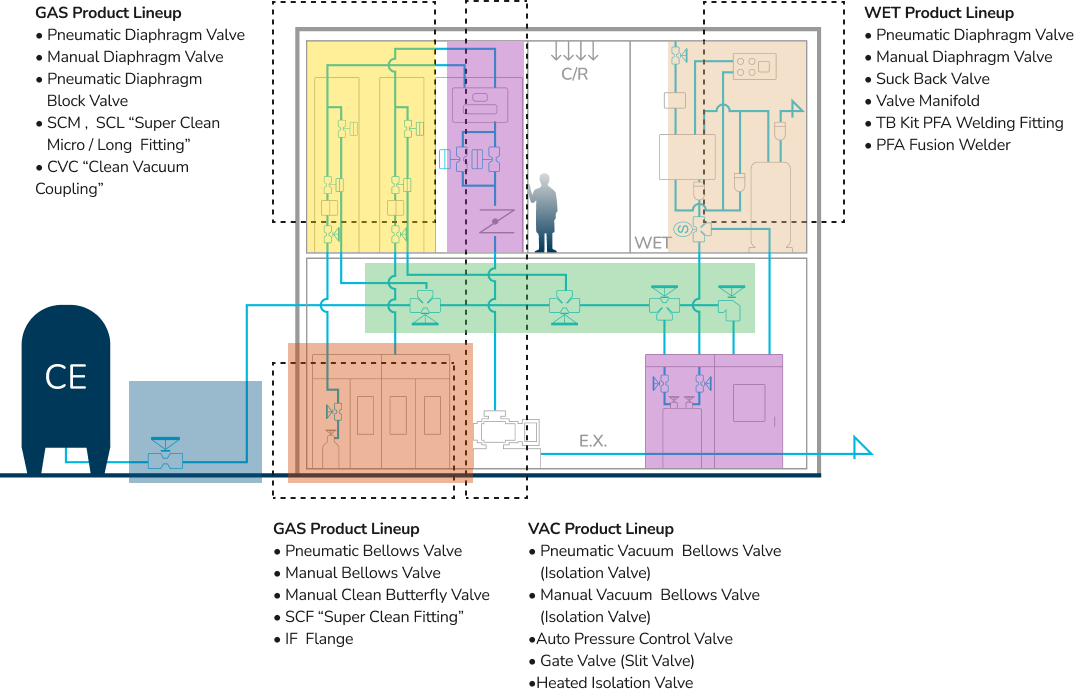

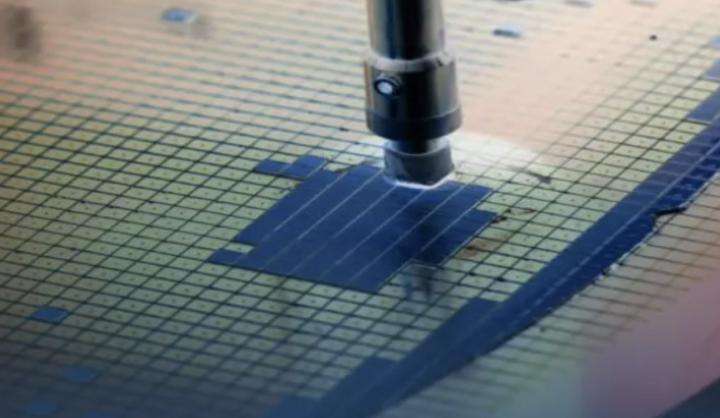

KITZ SCT provides products to a variety of industries that require ultra-high purity systems that are resistant to corrosive and toxic materials.

Supporting our customers with a wide range of product lineup providing complete solutions from UHP fluid components and systems: from gas delivery to vacuum exhaust.